Shock absorbers in off-road vehicles – how they work and which are best for off-roading?

In an off-road vehicle used as intended, the suspension has to work hard. Sometimes it almost has to do a split, but above all, it needs to provide stable handling over all the bumps you don’t intend to avoid. That’s why its parts, especially the shock absorbers, need some enhancement. How do different types of shock absorbers work, and which are best for off-roading? Let’s find out.

How shock absorbers work in a vehicle. Importance in fff-road conditions

Shock absorbers in 4x4s work extra hard, and without them, the ride would be wild. Let’s explain this more vividly.

Now, imagine driving without any shocks. Every time you hit a bump, all the impact force hits the wheels and is directly transferred to the suspension coil spring. With no damping element, the spring’s rebound amplitude is transferred directly to the vehicle body, causing intense and constant bouncing. Now, picture driving such a vehicle off-road, where ruts are everywhere.

Luckily, you’re not into such dangerous experiments. Your vehicle has shock absorbers installed which handle the energy from those impacts.

When you’re off-roading, the terrain constantly pushes your suspension to its limits. If your shocks aren’t up to the task, it’s not just about comfort—it can also impact your safety and control. That’s why having the right shock absorbers, suited to your vehicle and your driving style, is crucial. They improve traction, give you a smoother ride, and most importantly, allow you to tackle challenging terrain more confidently.

What a shock absorber is made of and how it works: structure and characteristics

Single-tube and twin-tube design

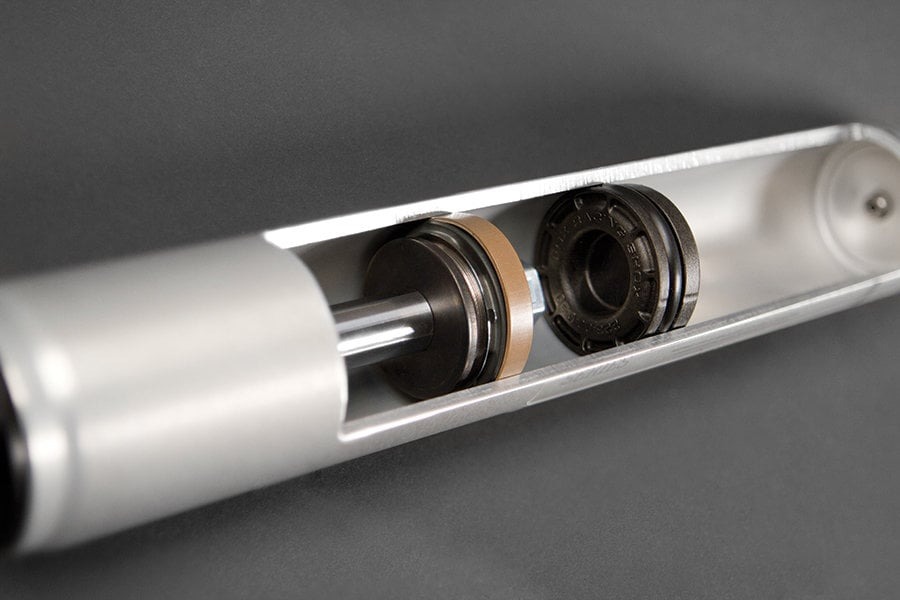

Let’s start from the beginning. Shock absorbers are divided into single-tube and twin-tube based on their design. Twin-tube shock absorbers are generally less advanced but reduce the risk of fluid mixing by using an extra inner cylinder. This limits the occurrence of cavitation—air mixing with oil, which reduces the shock absorber’s efficiency. On the other hand, a single-tube shock absorber deals with this issue thanks to an IFP (Internal Floating Piston) gas chamber that separates nitrogen from the liquid.

These two types of shock absorber designs can provide the required performance during off-roading. Getting into more detail, a typical shock absorber consists of:

- Upper and lower mounts

- Piston rod

- Piston rod guide

- Piston rod seal

- Piston at the end of the rod

- Valve discs on the piston

- Outer cylinder (or outer and inner cylinders)

- Reservoir

- Base valve

At first glance, a coilover, a shock absorber with a spring, might look different. The difference is mainly external due to the combination of the shock absorber with the spring. It resembles a McPherson strut from some front suspension setups but, unlike the McPherson, which is part of the steering system, the coilover is solely for shock absorption and suspension stabilization. Pickup owners are likely familiar with them.

Shock absorber – travel and stiffness

But how does the design of a shock absorber translate into real-world performance? When the wheel hits a bump and moves up and down, the shock absorber rod enters the cylinder, displacing the oil inside. In a standard oil shock absorber, the liquid flows through piston holes, bending the valve discs, creating resistance, and damping the suspension’s vertical vibrations.

If these discs are on both sides of the piston (top and bottom), the shock absorber works similarly during its return to the initial position. The stiffness of the shock absorber depends on these discs or plates’ specific characteristics.

Thanks to their special arrangement, the shock absorber can change its stiffness depending on the compression moment. For example, it may resist more during compression and work softer (rebound faster) during extension. Keep in mind this is a simplified explanation, as the same shock absorber behaves differently under a hard impact on the wheel than during cornering.

Which shock absorber for classic off-roading and overlanding?

If you don’t drive in tough and demanding terrain but still want shock absorbers with reliable performance, look for high-quality basic shock absorbers. The key is ensuring their design and technology effectively separate the liquid from the gas, which helps prevent oil from boiling and keeps your vehicle running smoothly even during exhausting drives over rough roads, gravel, or dunes. Therefore, the shock absorbers listed below are an optimal choice for longer off-road trips.

Single-tube gas shock absorber

This type of shock absorber contains degassed oil and pressurized nitrogen, separated by an additional floating IFP (Internal Floating Piston). This separation prevents the two substances from mixing, which helps eliminating the formation of air bubbles that could pass through the piston, reducing resistance. This setup significantly decreases the risk of cavitation.

Additionally, the gas chamber creates a reserve space that accommodates the movement of the piston rod, which is influenced by high nitrogen pressure. Compared to a classic oil shock absorber, single-tube shock absorber is stiffer and is an excellent choice if you are looking for balanced standard driving with off-road passion.

Twin-tube gas and oil shock absorber

These shock absorbers also combine oil and gas. However, in the case of twin-tube oil shock absorbers, the gas is under much lower pressure. The main difference between them and single-tube shock absorbers is the two cylinders, one of which is inside the shock. Often, these also feature two pistons, with a base valve at the bottom for compression damping.

In this setup, when the shock absorber compresses, oil passes through the base valve and flows into the outer chamber. The main advantage of this design is its low maintenance cost and high durability. Even with very intensive rod movement, the oil usually doesn’t mix with the gas because the piston doesn’t have direct contact with the gas chamber.

Related articles

Which shock absorbers for off-road racing and extreme off-roading?

If your main off-road activity involves driving in demanding and tough terrain, consider installing shock absorbers with more advanced technology. In racing, your goal is much closer, so the path to it is shorter and faster compared to overlanding. Unless you’re traveling through very mountainous terrain. In both cases, there is no time for cooling down, and a more versatile shock absorber performance is required.

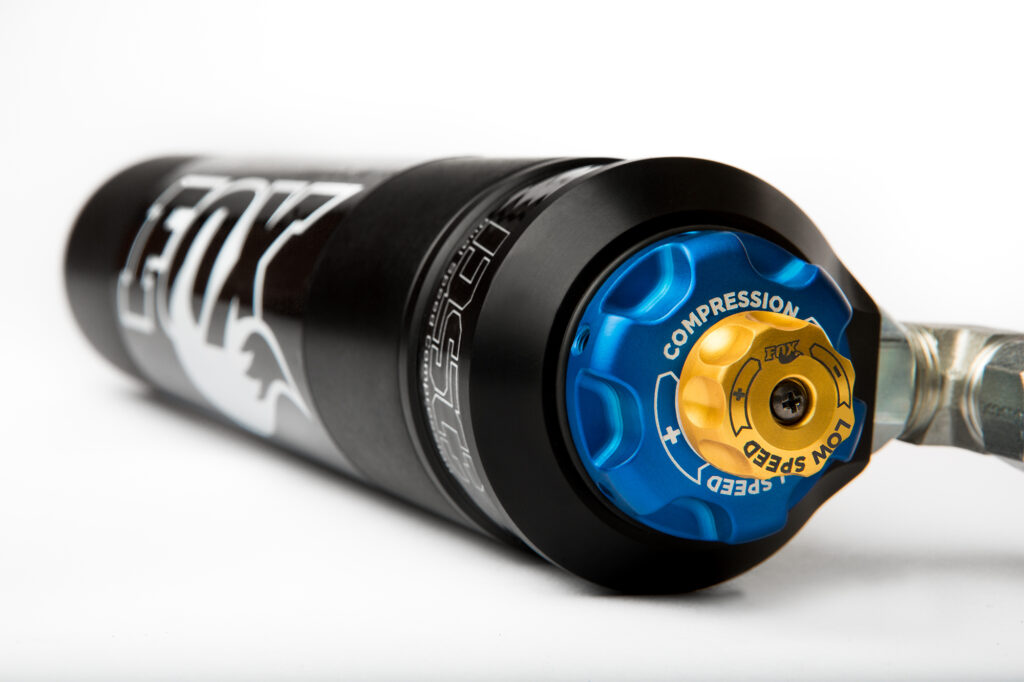

Shock absorber with reservoir

This shock absorber features a special external reservoir with extra oil and a low-pressure nitrogen chamber separated from the liquid by a floating IFP piston. Structurally, this is a variation on the single-tube shock absorber, but the absence of a nitrogen chamber allows the designer more calibration options. Low pressure and a potentially longer stroke for the same overall length compared to other models widen the range of possible configurations.

This design enables a softer, more sensitive initial compression, enhancing suspension flexibility and articulation. The larger oil volume and effective gas-oil separation also improve efficiency, reducing the risk of overheating or oil foaming.

Shock absorber with external or internal bypass

A bypass shock absorber is a more technologically advanced version of a reservoir shock. Its key feature is external bypasses positioned at various heights, each with pressure-regulated valves that control oil flow above or below the piston, adjcusting resistance. This offers greater customization to suit your driving style.

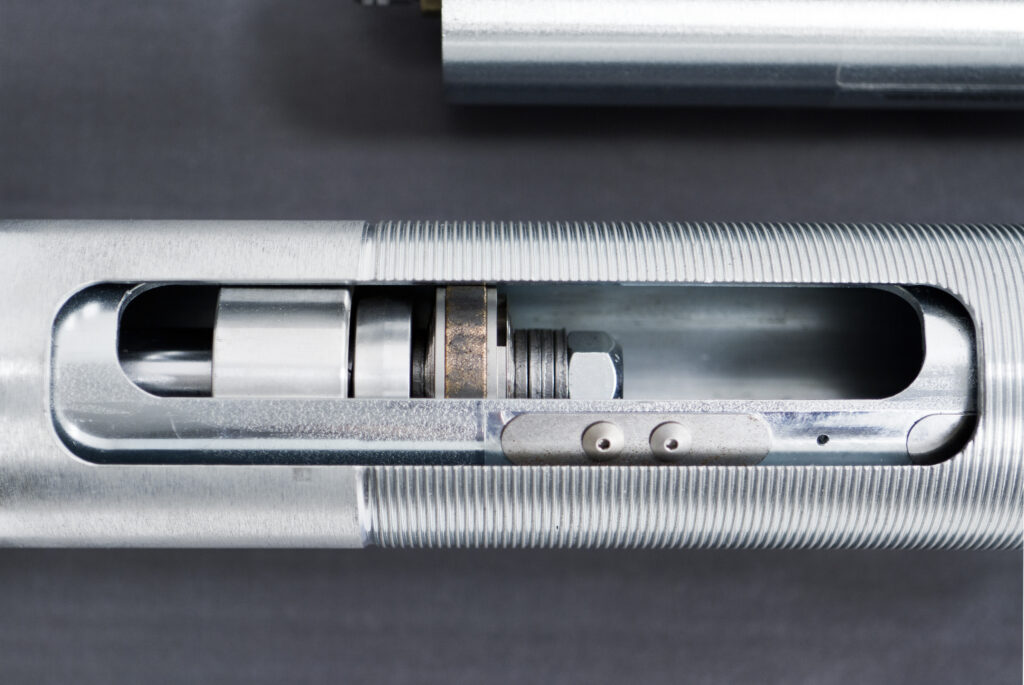

Internal bypass shock absorbers are a type of twin-tube shock absorber. Their inner cylinder is designed with special ports (bypasses) that act as resistance regulators, allowing oil to pass at appropriate compression and pressure levels.

In practice, this means the rod pushes fluid through these outlets during compression, into the outer cylinder part, making the maximum compression moment softer and more comfortable without a strong rebound that could jar your teeth during high-speed off-roading. This way, changing terrain shapes and surfaces are almost unnoticeable, having no negative impact on driving comfort.

What else can distinguish off-road shock absorbers?

An invaluable feature of off-road shock absorbers is additional stiffness adjustment. Being able to set it yourself allows you to better tailor the suspension’s behavior to your driving style. Generally, softer operation works better off-road, as it reacts more flexibly to every surface change.

Pneumatic, electric, and electro-automatic stiffness adjustable shock absorbers

There are several ways to adjust shock absorber stiffness. The most basic method is manual adjustment, meaning you have to manually turn the regulator on each shock absorber whenever you want to change the suspension’s behavior.

Another option is electrically controlled adjustment from the vehicle cabin. This doesn’t differ much from the adjustment on the cylinder but greatly improves the convenience of changing settings.

Selected Falcon and Fox shock absorbers also feature an automatic electric control mode. In these cases, a computer with a set of sensors detects braking, steering, driving speed, and impact force on the wheel. Based on the received parameters, they automatically adjust the shock absorber stiffness by regulating oil flow.

Why it’s worth replacing the shock absorber in an off-road vehicle: Summary

Although off-road vehicles are designed for driving off paved roads, in reality, most standard suspension components won’t pass a true off-road test. In a slightly better case, they won’t allow you to fully enjoy this sport.

Either way, replacing the shock absorbers with models better suited to off-roading will likely become necessary at some point in your off-road journey. It will certainly be necessary if you lift your vehicle’s suspension. When that time comes, it’s best to look for parts designed with off-roading in mind. What you mainly need to remember is:

- Off-road shock absorbers must effectively separate oil from gas to avoid fluid foaming and reduced performance.

- You can choose between twin-tube or single-tube shock absorbers with a floating IFP piston.

- Both designs can feature additional external or internal bypass networks (depending on the shock absorber type), which expand the shock absorber’s working range and increase its efficiency.

- Off-road shock absorbers can also include a reservoir to increase oil volume and stiffness adjustment, allowing better adaptation to conditions.

Comments ()